Our food-grade salt mill is receiving some important upgrades. This may cause some items to go out of stock, but the mill should have nearly double the capacity when the upgrades are finished.

We’re experiencing amazing growth at Redmond Life and have upgraded many of our systems, equipment, and processes to keep up with the needs of our loyal, passionate customers. For a long time, the mill we used to crush and sort our salt had more than enough capacity to keep our shelves stocked, but today it struggles to satisfy the demand, so we’re making some exciting improvements.

Our Current Food-Grade Mill and Why Upgrades are Needed

Real Salt is extracted from our salt mine using a food-grade, carbide-tipped rotary head that grinds the salt off the walls before it is scooped up and sent to our food-grade mill in a stainless steel-lined dump truck used exclusively for food-grade salt.

The food-grade mill is an entirely enclosed, stainless steel system that includes a crusher, two screens, and a metal detection system. The crusher, as its name implies, crushes the salt into different sizes. The screens “sort” the salt so the final product is the appropriate grain size. A series of magnets and metal detection system make sure no slivers from the equipment get into the Real Salt.

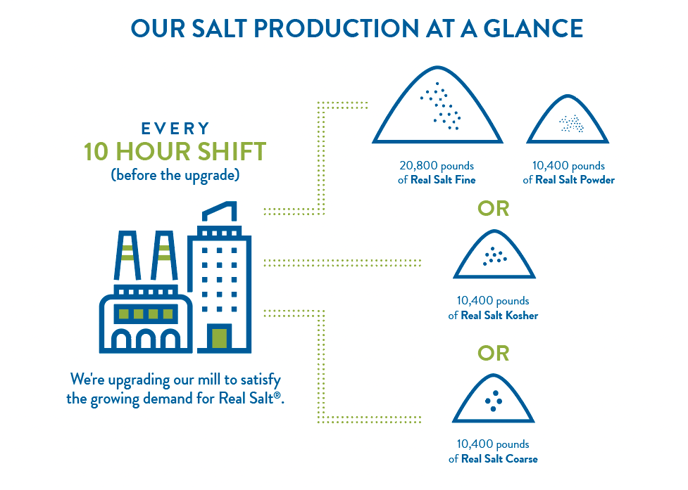

In a ten-hour shift, the mill can crush and screen about 20,800 pounds (over ten tons) of the Fine grain-sized Real Salt and 10,400 pounds of Powder. Production of Coarse and Kosher takes much longer and we get only 10,400 pounds in the same ten hours. 10,000 pounds is a lot of salt. And for many years it was more than enough to satisfy everyone’s Real Salt craving, but the mill needs an upgrade to keep pace with today’s demand.

Planned Upgrades for Early 2023

Planned Upgrades for Early 2023

Planning and preparations for the upgrade began more than a year ago. Our mill team worked with engineers to put together a design that would expand the current, two-screen system into a six-screen system. For now, we will only add two additional screens, nearly doubling our current capacity, but we will have the infrastructure to add another two screens, tripling today’s capacity, if demand continues to grow.

Construction began a month ago and most of it is complete. Our teams did everything they could to get the work done without stopping (or even slowing down) the mill. But we’re now at a point where we need to shut down the mill for at least a week and as much as four weeks (beginning on January 23, 2023) to finish the work and install the screens.

Impact on Customers

Our goal from the start of this process has been to reduce the impact on customers as much as possible when the mill takes its much-needed break. In addition to the ongoing construction, our dedicated mill team (and a few recruits) built up our Real Salt inventory by running extra shifts during the three weeks before the planned shut down. At the time of this writing, we had over 400,000 pounds of Real Salt sitting in our warehouse. Most of the Kosher and Coarse is needed to fulfill pending orders, so they will be out of stock until the upgrade is complete and the mill is back online. We hope to have enough Fine to get us through the upgrade. That said, it’s possible we’ll get behind if demand spikes or there are any unexpected challenges during the upgrade process.